- Home

- Page

How to convert CAD data into STL

STL File Creation for Different CAD Software Packages:

This page contains information on how to create an STL file from several CAD packages below. The information was taken from the Internet. Some of the information could be outdated or may not produce the best possible STL files in some cases, so please consult your CAD manual for instructions or the software developers for more information or technical support.

- Alibre

- AutoCAD (Version: R14-2000i)

- CADKey

- I-DEAS

- Inventor

- IronCAD

- Mechanical Desktop

- ProE

- ProE Wildfire

- Rhino

- SolidDesigner (version 8.x)

- SolidDesigner (version ?)

- SolidEdge

- SolidWorks

- Think3

- Unigraphics

STL (STereoLithography) is the standard file type used by most or all Rapid Prototyping systems. STL is a triangulated representation of a 3D CAD (Computer-Aided Design) model. The code for one triangle is shown below:

- solid test

- facet normal 0 1 0

- outer loop

- vertex 0 4 0

- vertex 0.517638 3.93185 0

- vertex 0.5 3.93185 -0.133975

- endloop

- endfacet

- endsolid test

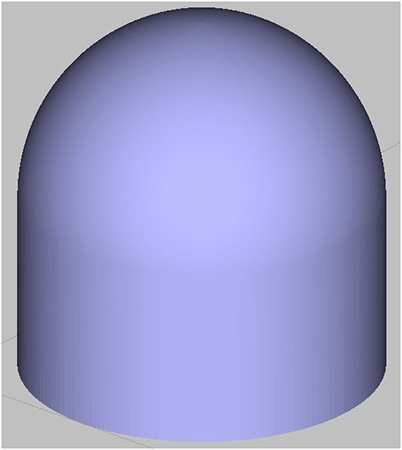

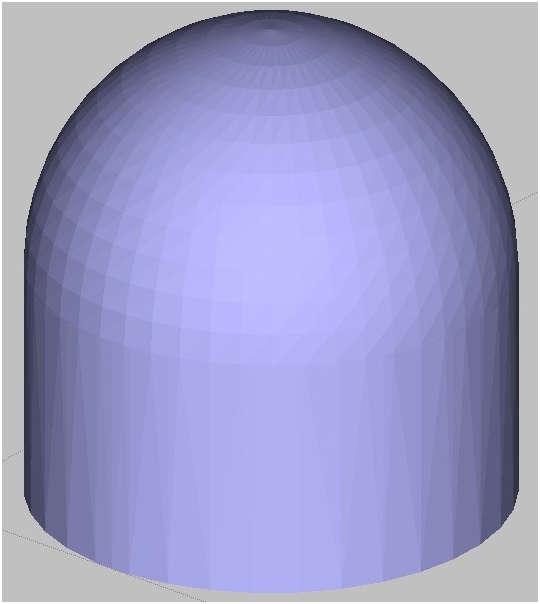

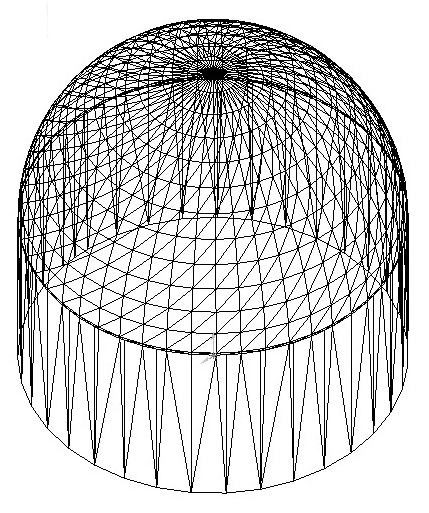

The triangulation of a surface will cause faceting of the 3D model. When exporting the CAD package to a STL file, you may see parameters for chord height, deviation, angle tolerance, or something similar. These are the parameters that will affect how much faceting occurs. You cannot build the model any better or smoother than the STL. So if the STL is coarse and faceted, that’s what you will see in the model. Although, you don’t necessarily want to go too small. The finer the STL is, the larger the file size will be, which will increase processing time in Insight as well as build time. Below are some examples of a fine and coarse STL:

Technical Information:

Stratasys Product Brief (pdf):

A chart that lists the results of tests conducted at Stratasys to establish the physical properties for PC and ABS utilizing the FDM process.

Material Safety Data Sheet (pdf):

MSDS for the P400 ABS from Stratasys.

Alibre

1. File

2. Export

3. Save As > STL

4. Enter File Name

5. Save

AutoCAD (Versions: R14-2000i)

Your design must be a three-dimensional solid object to output an STL file.

1. Make sure the model is in positive space

2. At the command prompt type “FACETRES”

3. Set FACETRES BETWEEN 1 &10. (1 Being low resolution and 10 high resolution for STL Triangles)

4. Next, at the command prompt type “STLOUT”

5. Select Objects

6. Choose “Y” for Binary

7. Choose Filename

CADKey

1. Choose Stereolithography from Export options

2. Enter the Filename

3. Click OK

I-DEAS

1. File > Export > Rapid Prototype File > OK

2. Select the Part to be Prototyped

3. Select Prototype Device > SLA500.dat > OK

4. Set absolute facet deviation to 0.000395

5. Select Binary > OK

Inventor

1. Save Copy As

2. Select STL

3. Choose Options > Set to High

4. Enter Filename

5. Save

IronCAD

1. Right Click on the part

2. Part Properties > Rendering

3. Set Facet Surface Smoothing to 150

4. File > Export

5. Choose .STL

Mechanical Desktop

1. Use the AMSTLOUT command to export your STL file.

2. The following command line options affect the quality of the STL and should be adjusted to produce an acceptable file.

3. Angular Tolerance – This command limits the angle between the normals of adjacent triangles. The default setting is 15 degrees. Reducing the angle will increase the resolution of the STL file.

4. Aspect Ratio – This setting controls the Height/Width ratio of the facets. A setting of 1 would mean the height of a facet is no greater than its width. The default setting is 0, ignored.

5. Surface Tolerance – This setting controls the greatest distance between the edge of a facet and the actual geometry. A setting of 0.0000 causes this option to be ignored.

6. Vertex Spacing – This option controls the length of the edge of a facet. The default setting is 0.0000, ignored.

ProE

1. File > Export > Model (or File > Save a Copy)

2. Set type to STL

3. Set chord height to 0. The field will be replaced by minimum acceptable value.

4. Set Angle Control to 1

5. Choose File Name

6. OK

ProE Wildfire

1. File > Save a Copy > Model

2. Change type to STL (*.stl)

3. Set Chord Height to 0. The field will be replaced by minimum acceptable value.

4. Set Angle Control to 1

5. OK

Rhino

1. File > Save As

2. Select File Type > STL

3. Enter a name for the STL file.

4. Save

5. Select Binary STL Files

SolidDesigner (Version 8.x)

1. File > Save

2. Select File Type > STL

3. Select Data

4. Click OK

SolidDesigner (not sure of version)

1. File > External > Save STL

2. Select Binary mode

3. Select Part

4. Enter 0.001mm for Max Deviation Distance

5. Click OK

SolidEdge

1. File > Save As

2. Set Save As Type to STL

3. Options

4. Set Conversion Tolerance to 0.001in or 0.0254mm

5. Set Surface Plane Angle to 45.00

6. Save

SolidWorks

1. File > Save As

2. Set Save As Type to STL

3. Options > Resolution > Fine > OK

4. Save

Think3

1. File > Save As

2. Set Save As Type to STL

3. Save

Unigraphics

1. File > Export > Rapid Prototyping

2. Set Output type to Binary

3. Set Triangle Tolerance to 0.0025

4. Set Adjacency Tolerance to 0.12

5. Set Auto Normal Gen to On

6. Set Normal Display to Off

7. Set Triangle Display to On

Contact Info

- 12, Mansarovar, Near Gaushala Circle, A.K. Road, Surat-395010

- (+91) 94279 77505

- info@3dtechno.in